Powder Spray Application Equipment

Manual Powder Spraying

The MS topcoat series represents the latest technological advances for manual and Automatic powder coating applications.

Emphasized ease of maneuverability and performance of the powder gun are exhibited through a streamlined and ergonomically balanced design, created to effectively reduce operator fatigue. An ultra-light gun weight increases operator productivity.

MS topcoat benefits from the latest in control technology. An easy to read operator touch screen control interface allows the operator access to simple and advanced control functions, even when wearing protective gloves.

Advanced feed-back signal control allows dramatically increased first-pass transfer efficiencies, amounting to considerably higher yields in powder application and productivity cost savings.

All guns are designed for ease of operator cleaning and maintenance. A minimum number of replacement spare parts ensure long life and reliability.

Manual Box Feed System

MS topcoater Box-Feed series of manual application equipment offers the latest in powder application technology to both industrial users, as well as job-shop / contract coaters. The Speedy is the latest in fast color change technology as applies to manual application equipment, making color change possible in under 30-seconds! Characterized by an ergonomic and simple rugged design, the MS topcoat is available in different configurations to suit every user’s specific needs. The modular design is easily expandable and offers a wide range of inter-changeable user specific

accessories.

All guns are designed for ease of operator cleaning and maintenance. A minimum number of replacement spare parts ensure long life and reliability. Both MS tribo and corona charged gun systems can be operated from a common control system.

MS topcoat benefits from the latest in control technology. An easy to read touch screen control interface allows the operator access to simple and advanced control functions, even when wearing protective gloves.

Advanced feed-back signal control allows first-pass transfer efficiencies of up to 70%, amounting to considerably higheryields in powder application and productivity savings.

Manual Hopper Feed System

MS topcoater Hopper Feed series of manual application equipment offers the latest in powder application technology to both industrial users, as well as job-shop / contract coaters.

Powder coating equipment users benefit from a fluidized tote feed system when using dedicated high volume colors, or metallic powders for consistent powder blending. Tote hoppers are easy to clean and can be conveniently stacked for storage when not in use.

The modular design is easily expandable and offers a wide range of inter-changeable user specific accessories.

All guns are designed for ease of operator cleaning and maintenance. A minimum number of replacement spare parts ensure long life and reliability. Both MS tribo and corona charged gun systems can be operated from a common control system.

MS topcoat benefits from the latest in control technology. An easy to read touch screen control interface allows the operator access to simple and advanced control functions, even when wearing protective gloves.

Advanced feed-back signal control allows first-pass transfer efficiencies of up to 70%, amounting to considerably higher yields in powder application and productivity savings.

Powder Color Change Systems

The booth enclosure is fabricated of high strength white PVC material. Double wall sandwich construction, with an air gap reduces static charge of the remaining powder keeping the walls, ceilings and floor clear of high powder accumulation.

Purpose designed ductwork connects the booth to the high efficiency cyclone. The trapezoidal configuration ensures the highest efficiency in powder reclaimation. In spray to reclaim operations, a minute volume of powder fines is purged from the incoming powder air mixture and ducted to the Absolute filter, where it is collected for waste disposal.

When in reclaim mode, the 97% efficient cyclone returns usable powder to the color kitchen via the integral parastaltic powder feed pump module. The cyclone and extraction duct are designed to be self-cleaning, further reducing the need for operator maintenance during routine color changes.

The color kitchen is equipped with an ultrasonic sieving device. The sieve removes any contamination, or powder clumps accumulated in the spray process and allows only classified powder particulate to return to the powder feed hopper tote. Fresh, or virgin powder can be automatically fed to the color kitchen, further keeping the system in total balance through either Big-Bag sack technology, or from boxes and cartons, using P50 high volume pump technology.

Powder Feed Kitchen

Automatic Powder Guns and Gun Movement

Of crucial importance for economical powder coating with many color changes is a powder kitchen with automated powder supply from the original powder container with monitored fresh powder feed. The easy-clean powder pump transports powder into the powder feed unit. The integrated MS Ultrasonic screening system guarantees clump free flowing powder with-out contamination. Automatic mode can be run with just 2-kg of powder. An integrated load cell located at the vibrating table weighs the powder container and gives an alarm if the minimal weight is not met. Automatic cleaning of the powder container, powder injectors, powder hoses and powder spray guns allow for fast color change.

An integrated exhaust fan reduces the chance for powder escape keeping the work area clean. Powder reclaim, or spray to waste modes are simply selected from the touch screen panel.

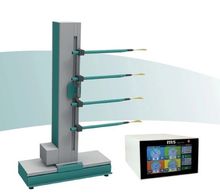

Automatic Powder Guns and Gun Movement

Automatic Powder Guns and Gun Movement

Precision and reliability in movement technology

Electronically controlled reciprocators with X-Y and Z axis movement

have been developed for efficient production operation in automated powder or liquid coating systems.

This sophisticated system can be expanded due to its modular design, from a simple control module and single axis movement, through to complex axis motion control systems using PLC controls.

Systems can be configured for manual operation or automated through light bar sensor packages. Sophisticated control for automated coating of enclosures, using Z-axis movement can be acheived.

Reciprocator stroke legths are available in increments to 12-M.

Reliability and robustness, as with all MS systems, is our trademark.

Wagner Flow Sense

Flowsense takes powder feeding with injector technology to a new level

At a glance:

- Fully automatic control of the powder quantity

- Ensures constant layer thicknesses

- Reliably reproducible results

- Reduces the amount of powder required

As part of the Flowsense technology, each individual feeding element in the powder center is equipped with high-precision measuring sensors. The smart system constantly monitors the powder flow and adjusts it to the target value. The powder quantity is continuously adjusted and deviations are automatically corrected. This also increases the reliability of your system.

WAGNER Flowsense – Digital precision in powder coating

TFS batch cartridge type powder coating bootH

Watch the start up and training of a batch powder system featuring the MS Powder box feed Elite applicator.

Video of our MS Powder Spray Equipment

Explore our advanced powder application technology! From manual and automatic powder guns to innovative recovery systems, quick color change solutions, robotic systems, and advanced gun movement technology—everything you need to enhance your efficiency is here!

6 Minute Color Change System

Check out this video showing a color change in 6 minutes with recovery!

Manual MS Topcoater in Action

Check out this video of our manual powder spray equipment!

Copyright © 2018 Total Finishing Solutions - All Rights Reserved.

Total Finishing is located at 1321 NE 76TH STREET, STE. 3E, VANCOUVER, WA 98665