Abrasive Blasting and Media Recovery

About Airblast-AFC

Our Partner Airblast AFC is a specialist provider of surface preparation and finishing solutions serving a wide range of industries from marine, civil and offshore to rail, aerospace and automotive.

We offer a complete service covering every part of the project from initial design and installation to training and servicing. Our skilled engineers work with our customers to create facilities that provide the highest levels of performance and efficiency. We offer turnkey blast and paint facilities suitable for a variety of applications including grit blasting, bead blasting, shot blasting, plastic media blasting, shot peening, wet painting and powder coating.

Airblast-AFC prides themselves on outstanding customer service and provide a beginning-to-end service, working closely with our customers throughout the project to ensure that they get the best possible solution for their chosen application. We have completed projects for a number of high profile clients, including built equipment specialist Mertz Manufacturing Ltd, The Rock Island Arsenal Joint Manufacturing and Technology Center in Illinois and the Missouri National Guard, providing them with high quality facilities and equipment that will continue to deliver superior performance for years to come.

Blasting windmill towers

Blast Rooms

Blast Rooms

Airblast AFC has more than 20 years™ experience in blast room manufacturing and has built a strong reputation for providing start to finish service on all of our installations..

Their rugged blast room designs, wide range of manual and automated abrasive recovery systems and carefully engineered ventilation systems have established our products as the equipment of choice for industry professionals throughout the world.

Airblast-AFC manufacture blast rooms, blast booths and related equipment for a wide variety of industries including aerospace, automotive, rail and wind power. Their comprehensive range of blasting rooms, blasting equipment and abrasive recovery systems provide a solution for almost any blasting application including grit blasting, steel grit blasting, bead blasting, shot blasting, plastic media blasting and shot peening.

When you enter into a contract with us, we will endeavor to make sure that you have all of the information you need about our blast rooms. We will start with an initial meeting to discuss your requirements and then guide you through the various types of blast room. We offer a range of designs including containerized blast rooms made from converted shipping containers, which offer a perfect solution when a cost-effective, transportable, weatherproof blast room is needed. We also offer modular blast rooms when a more custom blasting room is required.

Abrasive Blast Booth Interior

Containerized BLast Booth with Sweeper Floor Video

Get rid of screws and augers! Check out our Sweeper Recovery floors!

Containerized Blast Booths

Externally clad containerized blast booth

Externally clad containerized blast booth

Externally clad containerized blast booth

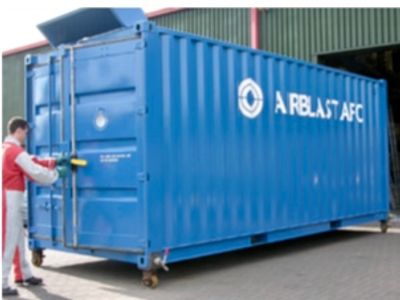

Airblast AFC containerized blast rooms are made from converted shipping containers, which provide an economical solution when a weatherproof and/or transportable blast room is required.

This versatile, mass-manufactured, watertight enclosure is an ideal starting point for a blast room, particularly when it may be relocated at some point or if it is to be situated outside in the elements.

Purpose built blast proof light modules

Externally clad containerized blast booth

Externally clad containerized blast booth

Airblast AFC re-engineers standard shipping containers to incorporate many of the same features found in our modular blast rooms. These include well designed ventilation systems, rubber curtains, purpose built light fixtures and advanced controls. Our containerized blast rooms may also be fitted with any of our media reclamation systems, ranging from our Vaculift to mini bucket elevators to full floor, automated recovery systems.

Full side opening booth option

Full recovery floor option eliminates manual clean up

Full recovery floor option eliminates manual clean up

Containerized blast booths are available with doors at one end, both ends or side and front opening. Where required they can be clad to match adjacent buildings.

Full recovery floor option eliminates manual clean up

Full recovery floor option eliminates manual clean up

Full recovery floor option eliminates manual clean up

Approximately a 3’ x 3’ area at the rear of the container is used to house the blast machine and media reclamation system, making the Airblast AFC containerized blast room a complete, self-contained system.

Where a full floor recovery system is fitted, the rear 9’ is dedicated to the recovery equipment.

Sweep Abrasive Airflex Recovery Floor

Airflex - Sweeper Floor Video

The Airflex Recovery Floor may be used with a wide variety of abrasive media

Dust Extraction Systems

Airblast AFC Dust Extraction Systems - Industrial shot blast dust extraction equipment

Airflex Sweeper Floor System

The Airflex Recovery Floor system is ideal for production shot blasting environments.

The Airblast AFC Airflex Recovery Floor System consists of modular corridors that sweep abrasive back toward an elevator. There are six corridors, each with a standard width. These can be produced to any length, allowing for recovery from virtually any floor area.

Flexible Scraper Blades

The Airblast AFC Airflex Recovery Floor System has rows of flexible blades installed at intervals across each corridor. The blades rest against galvanised steel combs that give them enough strength to push the abrasive. As they return, the combs pass through the abrasive and the flexible scraper blade passes over it without moving it. This back-and-forth motion gradually moves the abrasive to a transversal corridor that runs at right angles to the rest of the floor. This corridor transports the abrasive media to the elevator and the grit wash.

The grit wash includes a vibrating or rotary sieve and an air wash. From here, dust is sent to a dust collector, while spent abrasive and large contaminants are sent to a waste container. Diverting spent abrasive away from the dust collector in this way prevents premature wear of the collector elements, increasing value in the long term.

Dynamic Grit Wash

Dynamic Grit Wash

Operators are able to control the minimum size of particle that remains in the system by adjusting the power of the vacuum. The higher the power, the larger the removed particle.

Clean abrasive is deposited in a storage hopper equal in capacity to the volume of the blast machine. When all the abrasive in the blast machine is spent, or when the operator releases the activation handle, the blast machine is automatically charged with fresh abrasive from the hopper above.

Vaculift Type Media Recovery Systems

Airblast AFC Media Recovery - Vuculift Type

The Vaculift Recovery System provides a high recovery rate at an affordable price making it ideal for in-house blasting operations or where the production rate does not justify other, more complex, types of abrasive media recovery systems.

Screw Type Media Recovery

Airblast AFC Media Recovery - Screw Type Floor

These systems incorporate one or more auger screw conveyors, which typically include a series of longitudinal screws, along with a cross screw, which feeds the bucket elevator. Auger screws are generally laid out in an "H" configuration. Airblast AFC incorporates an adjustable baffle media metering plate covering and protecting the screw to prevent overloading.

AbVac Grit Recovery Unit

Perfect for use in restricted spaces in city centers or for difficult to reach locations like bridges, water tanks or gas towers, AbVac is one of the most portable recovery devices available anywhere in the world.

AbVac reclaims up to 10,000lbs of blast media an hour, has low power requirements, is highly effective with extended hose lengths, is low-noise, and is very simple to use.

Fan Blast Nozzle

Showing the advantages of a fan blast nozzles as compared to a traditional round nozzle. Fan blast is ideal for flat large surfaces. Contact us for a quote today!

Photo Gallery

Copyright © 2018 Total Finishing Solutions - All Rights Reserved.

Total Finishing is located at 1321 NE 76TH STREET, STE. 3E, VANCOUVER, WA 98665